Digitization and automation of your warehouse management

The fast pace of today's world requires support in logistics that allows you to meet the requirements of your customers. AXAVIAseries provides you with all functions for a modern warehouse management with the logistics module. The digitalization and automation of your warehouse management not only ensures order, but above all reduces your standing times.

The WMS Warehouse Management module provides you with all the functions for modern warehouse management. From the history of stock movements to the current storage locations of the products - the module knows the answers.

- The recording of stock movements is ensured by a barcode system.

- Batches & serial numbers ensure up-to-date tracking of products.

- Seamless data integration with the rest of the ERP software.

Construction site magazines are used as a special feature in plant construction. With the magazine management additional

convenient functions are available. Inventory lists facilitate a quick execution of the inventory.

Article management for inventory management

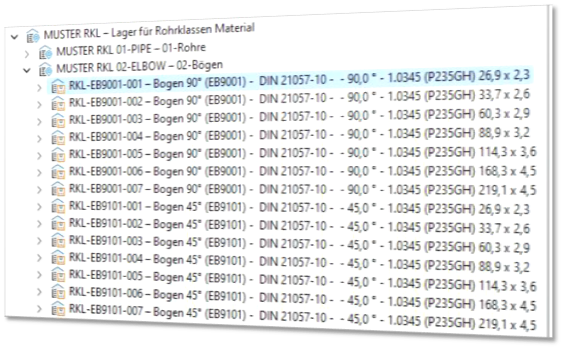

The material master forms the basis for the warehouse management. The basic data for each stock product is defined in the product catalog. In addition to the commercial product information, the warehouse information is also defined.

The information about the availability in the warehouse is available at any time and thus everyone has an overview of whether and which products are available in the warehouse.

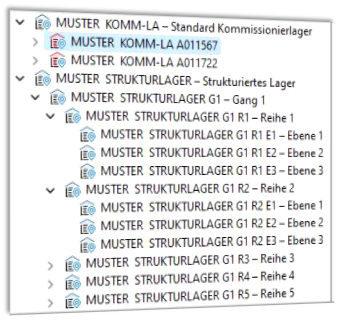

Warehouse structure according to your requirements

Within the scope of warehouse management, you manage any number of warehouse locations. Especially construction site warehouses are a special feature in plant engineering and can thus be managed easily and uncomplicatedly. To simplify procurement, the address data and standard storage locations are defined and automatically used for goods receipt and goods issue.

Structure your warehouses according to the real conditions via corresponding storage locations. There are no restrictions in the level of detail. Order-related commission warehouses are also available for easy project handling, where all order-related orders are temporarily stored until they are needed for assembly.

Automated inventory

A stock level is automatically created for each storage location and product. A separate stock is also defined to manage serial and batch numbers.

The warehouse stock also contains all information for inventory and goods movements. The warehouse valuation is also derived accordingly from this.

Uncomplicated inventory

The collection of the actual stock within the scope of an inventory is a fixed part of every company. AXAVIAinventory supports among other things a single and double inventory, whereby this can be carried out as a running inventory or as an inventory on a key date. Either you record the quantities in corresponding lists or immediately via barcode devices.

AXAVIA provides the corresponding lists for the recording of quantities or you do the recording directly via barcode devices. In addition to the quantity, the evaluation of the value of goods is also an important factor of the inventory. This results in the corresponding stock value.

Transparent stock movements

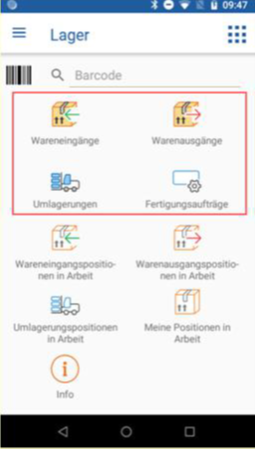

Stock movements are essentially goods receipts, goods issues and stock transfers in the warehouse or to another warehouse.

Stock movements are the main activities in the warehouse. Goods receipts are automatically planned with the purchase order. The planned delivery date results in the planned goods receipt. Conversely, the delivery date of the orders results in the planned goods issues. In this way, the warehouse manager always has an overview of when he has to carry out which warehouse movements and can organize the corresponding activities optimally. Via the various workflow transitions, he controls the goods movements and provides the corresponding feedback.

Create automated delivery bills

All goods receipts & issues at a glance

Clear warehouse management

Storage means are essentially mobile storage locations (e.g. boxes, pallets, bags, ...). Manage your storage media with AXAVIA and keep track of where they are at any given time.

You can now either move the products at the storage device or move the entire storage device. The relocation of the storage media moves the complete contents of the storage media with it.

Quick traceability through batch and serial numbers

Enter the batch and serial number for the goods movements quickly and easily. Via a search, you can immediately find those goods movements that relate to this batch or serial number. The corresponding storage location can be found at the push of a button.

In addition to the serial and batch numbers in logistics, a separate stock is maintained here for each serial or batch number.

Minimum and reorder point

It is important to have an immediate overview of stock levels that have fallen below the reorder level. Carry out the corresponding supplier orders directly in the warehouse management or pass them on to the purchasing department via BANF.

You can also activate a notification at any time when stock levels fall below a certain level, so that bottlenecks in production are finally a thing of the past.

Barcode support

For quick processing of the various tasks in the warehouse management, the warehouse management supports working with barcodes or QR codes. All documents must be equipped with barcodes accordingly.

Instead of manually entering the document numbers in the warehouse management, they are captured via a corresponding barcode reader and the respective process is triggered in AXAVIA.

Smart commissioning

Based on the planned outbound deliveries and stock transfers, the products are taken from the warehouse for an order and "collated" or picked.

Perform picking via appropriate mobile devices, where barcode support is of course also available.

Transparent incoming goods inspection

Incoming goods deliveries must be inspected in accordance with the quality specifications. This ranges from a simple quantity check to visual inspections and concrete measurements of various properties.

The various statuses are controlled via the workflow and the quality inspections are documented via checklists and measurement lists. It is also possible to store photos.

Mean value method for bearing evaluation

The value of the inventory significantly determines the balance sheet in many companies. AXAVIA supports the user in determining the inventory value on a certain key date.

The calculation is carried out using the mean value method. This means that a new average value for the product is calculated with each goods receipt of a product.