The engineering software for from pre-project to detail engineering

Plan your project quickly and easily. AXAVIAedb offers optimal support from the preliminary project, through basic engineering, to detail engineering.

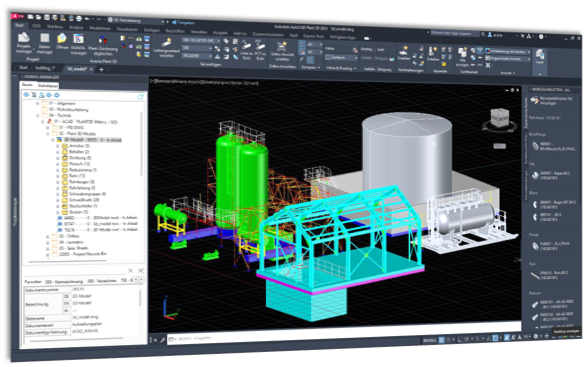

Due to the CAD integration AXAVIAseries becomes an integrated planning tool. CAD and project planning data flow together and are dynamically available.

AXAVIAedb provides a predefined data model for process engineering, plant engineering, electrical engineering, automation engineering and mechanics in an amazing level of detail. Libraries and reports supplied specifically for the respective area create a working environment with high productivity.

Through the engineering database you have access to all your engineering data anytime and anywhere and increase your productivity and quality in your engineering projects.

Do you want to successfully digitize your engineering processes? Find out more in our module information.

Project and document management for your engineering projects

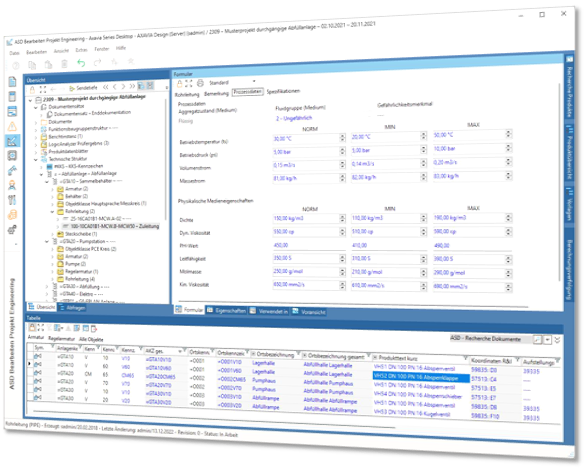

The basis of the engineering database is the project management. Organize and structure your engineering in projects and create the necessary overview.

Documents are a central component in engineering. Manage your documents in the engineering projects and create access to the current documents for everyone involved.

Project overview

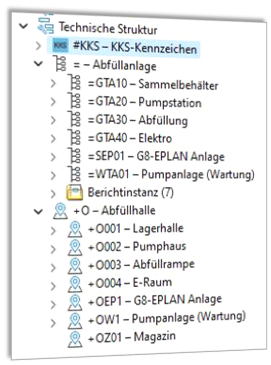

Detailed technical structure

Technical details

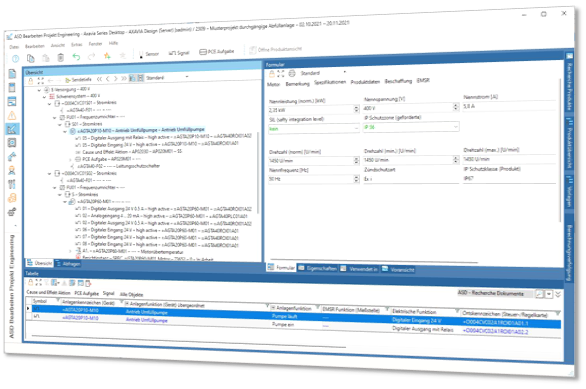

Standardized plant and location structure for your plants

The plant structure organizes and structures a plant according to the function of the plant. In most cases, the plant structure is used as the basis for the labeling system. Create any plant structure and thus define almost any plant identifier, which is completed in the plant-specific components.

In addition to the plant identifier, a location information is also used as part of the identification system, especially for large plants. Organize your plant according to any location structure and use this as additional information for the respective components as location information.

PPS or RDS-PP structure

In power plants and similar facilities, a standardized VGB marking system according to KKS or RDS-PP has become established. The engineering database allows you to set up your marking system according to KKS or RDS-PP. Please note that the KKS or RDS-PP structure is not part of the scope of delivery, as it is protected by VGB and must be explicitly purchased by VGB.

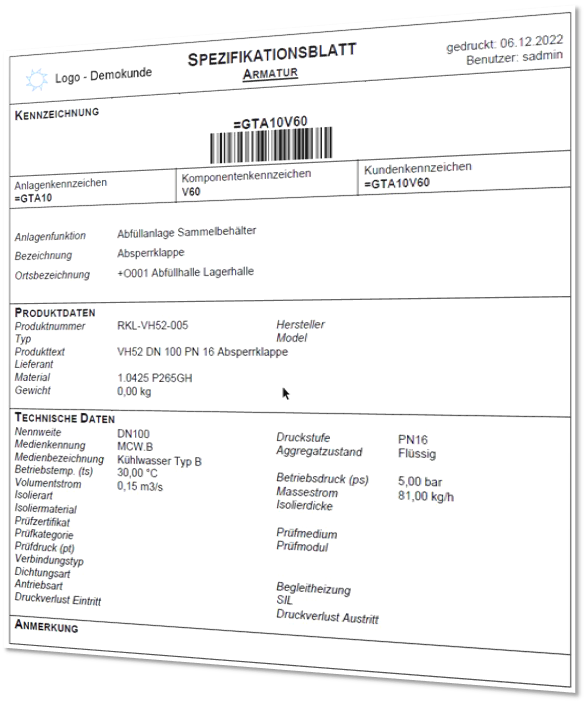

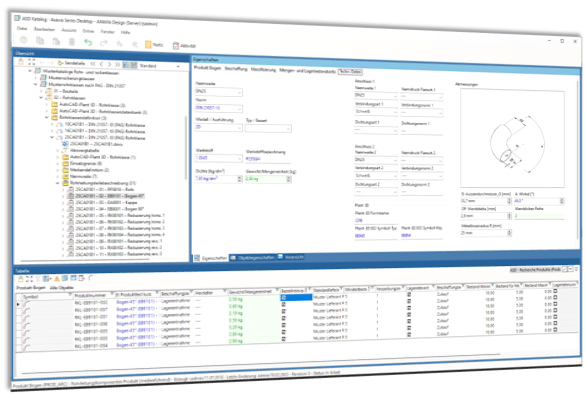

Specification sheets for careful documentation of your equipment

Specification sheets are documents that describe the technical requirements and characteristics of a product or plant. They serve as a guide for the development, manufacture, inspection and commissioning of the product or plant.

Specifications include information on materials, sizes, weights, performance characteristics, connections, interfaces, safety requirements and other relevant factors. This information is created in the engineering process to ensure that the product or equipment meets the requirements and functions properly. The specification sheets also provide a reference for future procurement requests, as well as for maintenance and repair work on the equipment.

They are generated and managed as reports by AXAVIA. The content corresponds to the information of the components.

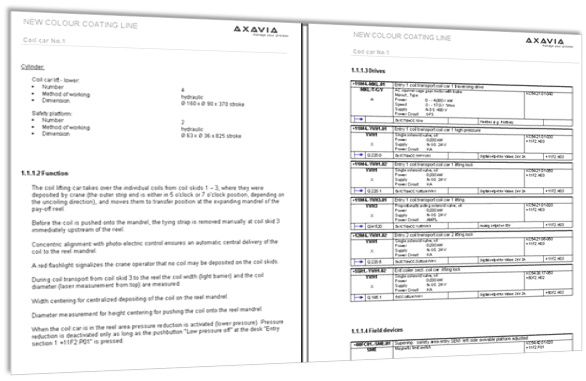

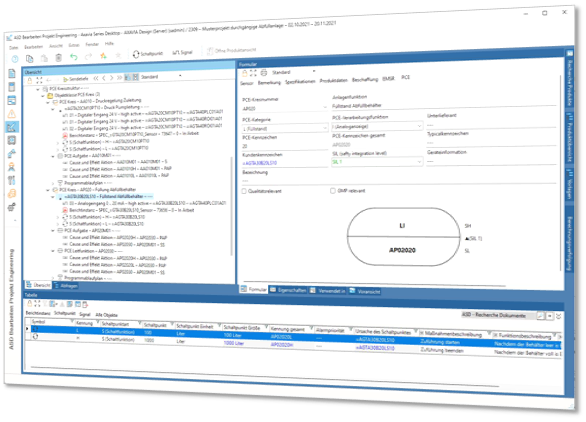

Functional description of your plant

Functional descriptions are an important part of the documentation. Besides a verbal description, a lot of technical information of the components is included.

The functional description is a documentation of the operation of the equipment. For this purpose, the documentation is structured in corresponding chapters and described verbally. For the integration of components, these are linked to the respective chapter and merged in the generated documentation.

The generated documentation always accesses the current planning status and is therefore always up to date.

Especially the support for translation into other languages is a significant advantage for the user.

All spare parts at a glance

A spare parts list for plant engineering is a document that contains a list of the spare parts that are required for a particular plant. It gives an overview of the parts that need to be replaced regularly or should be available quickly in case of failure.

The list usually contains information such as part number, description, manufacturer, supplier and stock level. Such a list is of great importance for the plant operator as it monitors the availability and stock of spare parts and ensures that the plant is always ready for operation. Define your spare parts in AXAVIA and thus create the spare parts list for documentation at the push of a button.

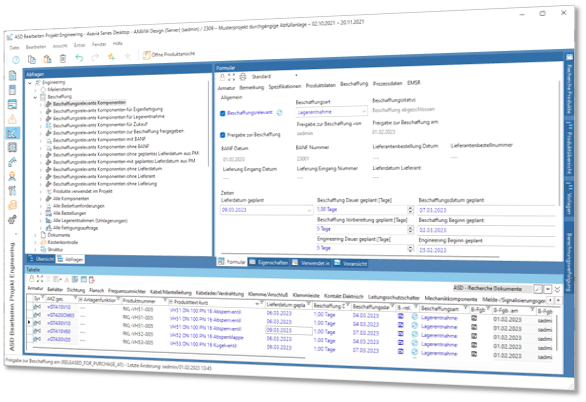

Efficient procurement processes with parts lists

The engineering database defines the bill of materials for your project. The exact specification of the parts describes each component in detail. This parts list is also the basis for procurement. Define which components have to be procured and how (purchase, customer provision, ...). On basis of the prepared parts list the data are prepared for the procurement.

Procurement date

The delivery date is taken over either from the project management, or deposited directly in the parts list. By the deposited procurement duration then over a backward scheduling a procurement date is determined.

Procurement release

The technical manager releases the BOM entries for procurement.