PPS Software zur Fertigungsplanung –

alle Vorgänge in der Fertigung geplant, gesteuert und überwacht

Ausgehend von den Bedarfsanforderungen und Fertigungsaufträgen ist die Planung der Produktion das Kernelement in der Fertigung. Planen, steuern und überwachen Sie alle Vorgänge in der Fertigung. Stellen Sie sicher, dass die Ressourcen und Materialien für die Fertigung ausreichend zur Verfügung stehen. Das Modul unterstützt Sie in der gesamten Prozesskette vom Fertigungsauftrag, bis zur Auslieferung. In Kombination mit der Zeiterfassung haben Sie jederzeit die Kontrolle der tatsächlich eingesetzten Ressourcen.

Verkaufsprodukte werden mit den hinterlegten Stücklisten in Einzelpositionen zerlegt und stellen die Basis für die Bedarfsplanung der benötigten Materialien dar. Vordefinierte Arbeitspläne ergänzen die Planung und die notwendigen Arbeitsschritte und legen so die einzuplanenden Ressourcen fest. Mit Hilfe von Arbeitszeitmodellen und Bearbeitungszeiten unterstützt Sie AXAVIApps in der Kapazitätsplanung.

Basis für die Auftragsdurchführung sind die von der Arbeitsplanung in den Arbeitsplänen festgelegten Arbeitsabläufe und Vorgabezeiten. Weitere wichtige Daten sind die in der aktuellen Situation zur Verfügung stehenden Kapazitäten von Mitarbeitern, Maschinen und Betriebsmitteln, d.h. die Anzahl verfügbarer Arbeitsstunden in den zukünftigen Zeiträumen.

Fertigungsplanung leicht gemacht

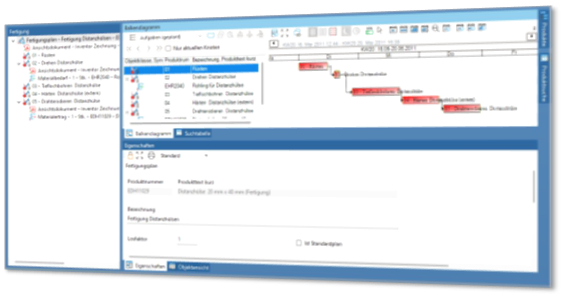

Über den Fertigungsplan definieren Sie jene Fertigungsschritte, welche für die Produktion eines Produktes notwendig sind. Benötigen Sie für einen Fertigungsschritt weiteres Material, wird dies über den Materialbedarf erfasst. Sollten bei einem Fertigungsschritt Produkte entstehen, so entsteht ein Materialertrag. Für die Fertigungsschritte werden noch die benötigte Dauer für das Rüsten einer Maschine oder die Durchführung eines Fertitungsschrittes und die dafür notwendigen Ressourcen festgelegt.

Somit sind alle notwendigen Definitionen getroffen, um ein Produkt in einem Produktionsplan automatisch einzuplanen und die entsprechenden Arbeitsschritte in der Fertigung festzulegen. Auch die Ressourcenzuteilung kann weitgehend automatisch erfolgen.

Fertigungsplan inkl. Ansichtsdokumente

Gantt – Darstellung

Fertigungsauftrag

Ausgehend vom Fertigstellungstermin werden über die automatische Rückwärtsterminierung die einzelnen Fertigungsschritte zeitlich eingeplant, wobei jederzeit manuell nachjustiert werden kann. Für die Planung der Zeitdauer werden die hinterlegten Ressourcen und die Stückzahlen verwendet. Die Freigabe für die Fertigung erfolgt über einen entsprechenden Workflow.

In einem Gantt Diagramm haben Sie den Überblick, wann Sie welche Aufgaben zu erledigen haben.

Materialbedarfsermittlung & Disposition

Basis für eine automatische Bedarfsermittlung ist die jeweilige Produktstruktur aus dem Materialstamm. Die Produktstruktur definiert über den jeweiligen Materialbedarf, welche zusätzliche Materialien (Sekundärbedarf) bei der Fertigung benötigt werden.

Ein Dispositionslauf ermittelt einerseits das benötigte Material und andererseits die daraus entstehenden Erträge. Das können geplante Lagerentnahmen oder Bedarfsanforderungen sein.

Es werden dabei neben den benötigten Produkten auch die entsprechenden Termine automatisch übernommen und bei der Bedarfsanforderung ausgefüllt. Die weiteren Bedarfsanforderungen werden dann wieder durch Zukauf oder erneuter Eigenfertigung der benötigten Bauteile gedeckt.

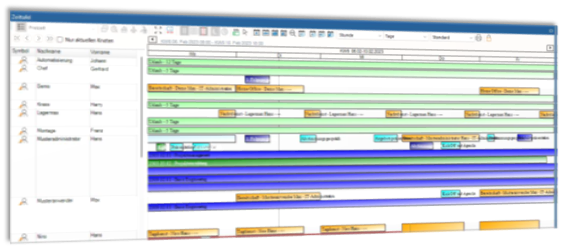

Ressourcenauslastung

Pünktliche Lieferung durch optimale Ressourcenplanung

Wann gibt es noch freie Kapazitäten, um einen Liefertermin für einen Auftrag zu nennen? Diese und ähnliche Fragen stehen auf Ihrer Tagesordnung. AXAVIApps liefert Ihnen auf Knopfdruck die Auslastung Ihrer Ressourcen. Freie Ressourcen und Überlastungen sind augenblicklich erkennbar.

Als Ressourcen stehen einerseits Mitarbeiter und Maschinen, aber auch Räume oder Kraftfahrzeuge für die Kapazitätsplanung zur Verfügung. Andererseits ist es oft hilfreich, Ressourcen nicht im Detail zu definieren, sondern nur eine Ressourcegruppe in Form einer Abteilung oder einer bestimmten Qualifikation festzulegen, um so die entsprechende Auslastungsinformationen zu erhalten.

Auf Basis der geplanten Fertigungsaufträge mit deren Fertigungsaufgaben mit den definierten Ressourcen (Maschinen, Arbeitsplätze, Mitarbeiter) wird die Ressourcenauslastung ermittelt.

Die Terminplanung erfolgt dabei automatisch mit einer Rückwärtsterminierung der Fertigungsaufgaben auf Basis der Abhängigkeiten und dem definierten Fertigstellungstermin.

Der Abgleich der Ressourcen bei Überlastung erfolgt dabei manuell durch die Arbeitsvorbereitung.

Arbeitskarten mit Barcodeunterstützung

Die jeweiligen Fertigungsaufträge können als Arbeitskarten ausgegeben werden und bilden so die Grundlage der Abarbeitung in der Fertigung. Die Arbeitskarten dienen als Begleitkarte und

durchlaufen mit den Produkten die Fertigung. Die Arbeitskarten können mit Barcodes ausgestattet sein, damit eine effiziente Abwicklung in der Fertigung möglich ist. Dabei werden einerseits die Zeitbuchungen und andererseits der Status der jeweiligen Arbeitsschritte gebucht.

Nutzen Sie die Arbeitskarten oder Laufkarten mit Barcodes entweder am BDE Terminal zur Rückmeldung oder mit der Lagerapp um die Lagerbewegungen komfortabel durchzuführen.

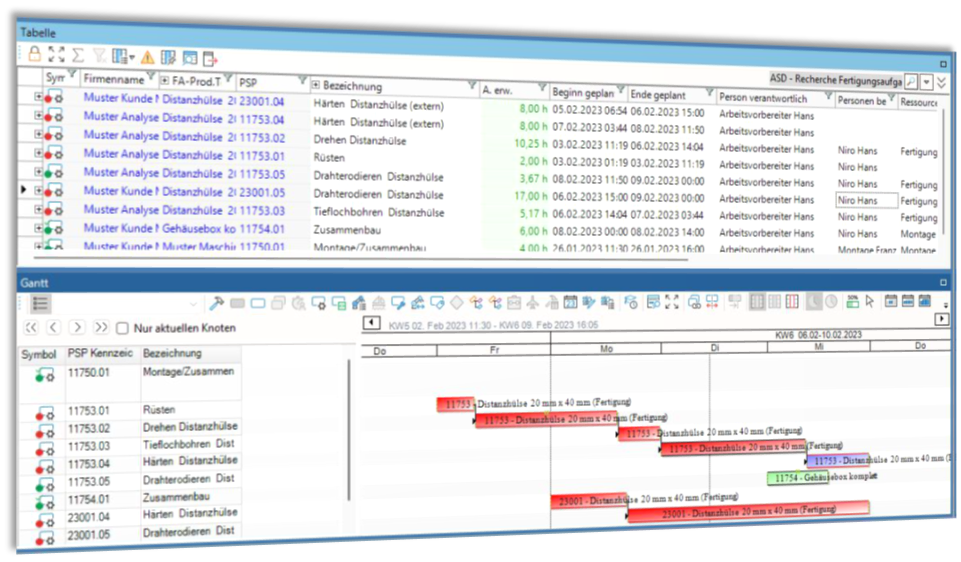

Übersichtlicher Terminplan & Plantafel

Basis für eine optimale Terminplanung ist eine Übersicht der anstehenden Fertigungsaufträge. Wann müssen welche Aufträge erledigt sein? Dazu haben Sie jederzeit auch Zugriff auf die Kundenaufträge und wissen wann die Liefertermine zum Kunden anstehen. Sind Fertigungsaufträge überfällig und nicht erledigt, erhalten Sie eine entsprechende Benachrichtigung. Das Ergebnis der Planung der Fertigungsaufträge, deren Fertigungsaufgaben und Zuteilung zu den Ressourcen ist ein konkreter Fertigungsplan für die Fertigung.

Für die geplanten Fertigungsaufträge stehen Ihnen unterschiedliche Darstellungen zur Verfügung:

Tabelle

Die tabellarische Darstellung ist vor allem dann hilfreich wenn Sie eine schnelle Filterung, Sortierung oder eine Massenbearbeitung der Daten durchführen möchten.

Plantafel

Die Plantafel zeigt Ihnen schnell und übersichtlich welche Fertigungsaufträge wann auf welchen Maschinen und Ressourcen abgearbeitet werden.

Gantt Darstellung

Das Gantt Diagramm stellt die anstehenden Fertigungsaufträge zeitlich übersichtlich dar und zeigt Ihnen mögliche Verzögerungen sofort an indem der Status der Fertigungsaufträge farbig dargestellt werden.

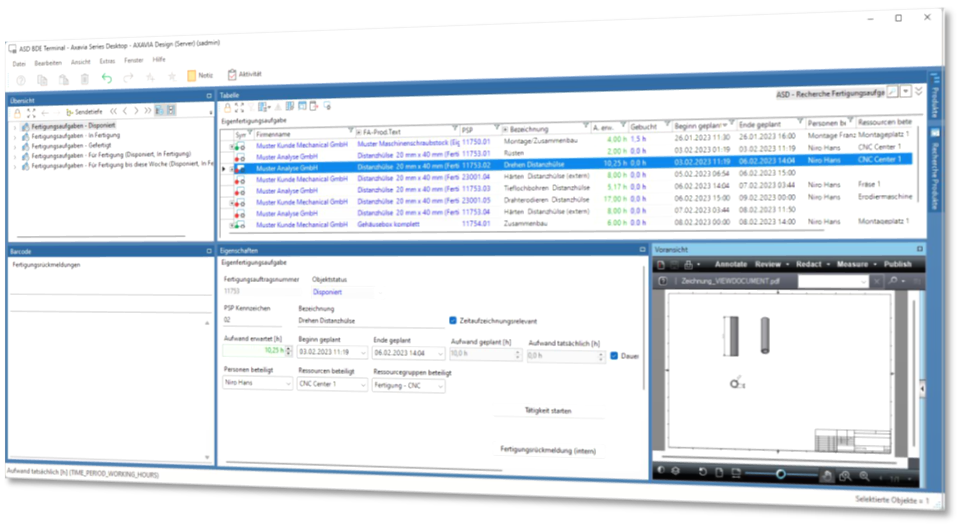

Smarte Fertigungsrückmeldung

Zur schnellen und einfachen Übersicht der aktuellen Situation in der Fertigung ist vor allem eine zeitnahe Rückmeldung der erledigten Arbeitsschritte notwendig. Einerseits ist dies manuell über AXAVIApps möglich, andererseits ist ein Barcodelesegerät eine optimale Ergänzung bei der Rückmeldung. Nach der Fertigstellung von Fertigungsaufträgen erfolgt eine Rückmeldung an das PPS System. Dazu steht Ihnen das AXAVIA DBE Terminal zur Verfügung, welches für die Rückmeldung in der Fertigung optimiert ist. Diese wird vorzugsweise über Barcodeunterstützung erfolgen.

Die Rückmeldung berücksichtigt vor allem 3 Themen:

Zeitrückmeldung

Mit dem Scannen von Beginn und Ende der Tätigkeit wird die benötigte Arbeitszeit auf die jeweilige Fertigungsaufgabe gebucht und liefert die notwendigen Informationen für die Nachkalkulation. Neben der Arbeitszeit der Mitarbeiter auch jene der verwendeten Maschinen. Somit ergeben sich aus der Maschinenzeit die entsprechenden Kosten, welche für die weitere Kostenauswertung berücksichtigt werden.

Mengenrückmeldung

Neben der Arbeitszeit sind natürlich die gefertigten Mengen von wesentlicher Bedeutung, um den weiteren Prozess zu steuern. Dabei werden auch gleich eventuelle Ausschussmengen erfasst.

Lagereingang

Nach Abschluss der Fertigungsaufgabe und erfolgreicher Qualitätsprüfung werden die entsprechenden Mengen auch in das Lager gemeldet und stehen somit für die weitere Verwendung zur Verfügung. Hinterlegen Sie bei den einzelnen Warenbewegungen die Serien- oder Chargennummer, welche in der Fertigung insbesondere beim Zusammenbau von Baugruppen immer wieder notwendig sind.